Toshiba's Contributions to India through Thermal Power Generation Technology

- Building on the past, realizing the future

The use of coal is almost as old as civilization itself - as long ago as the 5th century BC, it fueled ancient Greek forges that worked metal. Commercial mining began in England a thousand years later, and in the 18th century Industrial Revolution coal provided the primary energy source for industry and transportation. Naturally, the first ever power plant, built in the late 19th century, was coal fired.

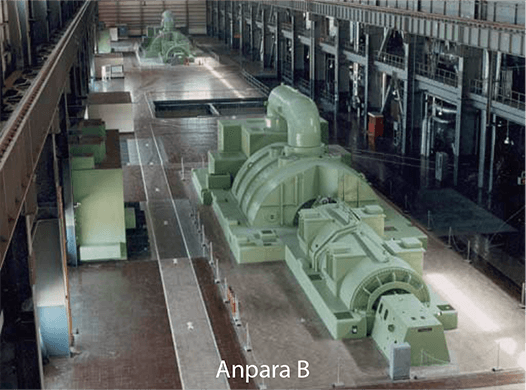

Toshiba entered the scene less than 50 years later, when it delivered its first steam turbine in 1928. Since then, the company had manufactured and delivered over 1,900 steam turbines around the world. In India, Toshiba supplied its first steam turbine and generator to the Anpara B Thermal Power Station in Uttar Pradesh, helping to realize a stable source of electricity for the local population.

In this issue of the newsletter, we want to look briefly at Toshiba's work in India, and our future ambitions here.

Building a presence in India

Nearly 25 years ago, a Japanese businessman in his 30s sat at his desk in Delhi, waiting for the phone to ring. When it did, he listened intently, and then let out a sigh of relief. The news was good. Anpara B Thermal Power Station had started commercial operation without any problem. His concerns slipped away, transforming into excitement and a sense of accomplishment.

Back then, Toshiba was working to build its overseas operations, and the young businessman was a member of Toshiba's Power Systems Division sales team covering India and Southeast Asia. With his colleagues, he was working to establish a presence in new markets, and had been given a crucial mission: successful installation and commissioning of steam turbines and generators at Anpara B. After witnessing the completed project with his own eyes, he returned to Japan to help build on that crucial success.

In the years that followed, more orders came: supply of combined-cycle power-generation systems to the AP-GAS Vijjeswaram CC Thermal Power Station in Andhra Pradesh, and for five 800MW supercritical steam turbine and generator units for the Mundra Power Plant in Gujarat, which started commercial operations in 2012. Current operations include manufacturing seven 600MW, 800MW-class turbines and generators to meet new orders. And that's not all. As Toshiba reinforced its reputation in the Indian power equipment market, it also expanded its capabilities to include turnkey plant supply. That move bore fruit in 2015, with the award of an EPC contract for the Harduaganj Ultra-Supercritical Thermal Power Project from the plant owner, Uttar Pradesh Rajya Vidyut Utpadan Nigam Ltd.

Many of these activities were directed by the same businessman in the Delhi office, a man who eventually returned to India as Chief Marketing Executive of Toshiba JSW Power Systems (TJPS), and who is now Managing Director of Toshiba India Private Limited (TIPL) – Tomohiko Okada.

A major contributor to Toshiba's recent successes in winning orders in India is our turbine and generator production facility in Chennai. This was established as the predecessor to today's TJPS in 2008, a full six years before the Indian government introduced its “Make in India” initiative. Mr. Okada explains why: “We wanted to take our international business to the next level by building our first power systems manufacturing facility outside Japan. We recognized that India had great potential and the capable people we need. It's a growing market, and its strategic position makes it an ideal location for exporting to the global markets.”

Asked about how well that strategy has worked, Yoshiaki Inayama, the current Managing Director of TJPS recalls, “TJPS successfully delivered its first large-scale turbine in 2014, and a 400-ton generator followed in 2016. I think our success so far stems from the determination of our Japanese staff to assure Toshiba's quality standards in India, and the great efforts of all our Indian staff, who have done everything necessary to realize it.”

Today, TJPS is positioned to offer comprehensive one-stop solutions that cover Engineering, Manufacturing, Procurement, Construction and Service (EMPCS). The company has allowed Toshiba to achieve cost competitiveness through localization and to provide exceptional services with speed.

From “Make in India” to “Export from India”

India's economic growth continues to drive demand for power capacity expansion, and the government has recently indicated that it is discussing putting more weight on renewable energy in the 5-year plan for 2018-2022. That brings a degree of uncertainty into the future outlook for thermal power generation, but TJPS is ready. The company has set its sights on becoming a global provider of thermal power products and services, an approach in line with the government's “Export from India” initiative, and is already supplying turbine parts to the U.S. market. From a broader perspective, Toshiba now has core manufacturing bases in Japan and India, and will build a business model for exporting products and services to the global market.

Toshiba India Strengthens Ties Among Toshiba Group

Toshiba Group is committed to a strong presence in India, and ensuring this is the main mission of the Toshiba India Private Limited. TIPL takes the lead in developing strategy and planning, promoting business activities, coordinating the seven other subsidiaries, including TJPS, and liaising with the Indian and Japanese governments. It is in the safe and able hands of Mr. Okada, a man who had dedicated many years of his career to cultivate Toshiba's business in India.

Messrs. Okada (sitting) and Inayama (standing) both joined Toshiba in 1983. Both have devoted themselves to the power systems business, Mr. Okada in sales, Mr. Inayama in production. They are both passionate about what they do, and are taking on all the challenges necessary to guide Toshiba's energy and capabilities FOR THE NEXT INDIA.

NEXT GENERATION TECHNOLOGIES

From the glowing incandescence of the large shopping complexes seen from the city highway to the factories crowding the industrial zones on its outskirts, Delhi is a constant reminder of the vast and increasing amounts of electricity that fast growing India consumes.

Today, 70% of that electricity is produced from thermal power generation - and as one of the most reliable, well developed and widely used form of generation, thermal power is projected to be the mainstay of power source to meet the country's needs for years to come. While the government's new energy policy calls for greater use of solar power and other renewables, thermal power plants will long continue to play a central role in securing stable energy supply.

That is why Toshiba is promoting a range of technical approaches to provide sustainable power through thermal power in India.

Improved generation efficiency demonstrate solutions to problematic CO2 emissions

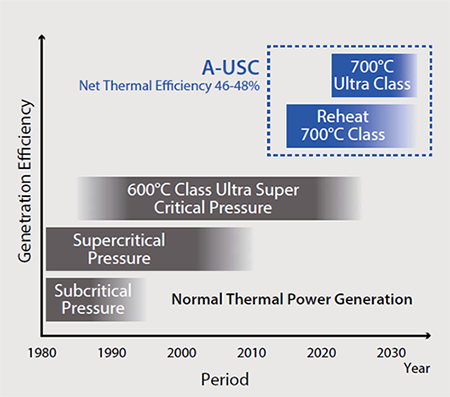

The power industry is increasingly called on to reduce carbon dioxide emissions, including those from coal-fired power plants. There are two main approaches, one centering on improving generation efficiency. Increasing steam temperatures and pressure allows plant to produce electricity more efficiently, meaning that there will be less consumption of fuel (coal) and lower emissions of carbon dioxide.

Toshiba continues to make considerable progress in developing thermal power technologies that meet both environmental and generation efficiency challenges by operating at very high pressures and temperatures. The steam condition in steam turbines can be categorized into two types: Subcritical

(Sub-C) pressure and Super Critical (SC) pressure. The latter was developed over the years, from the initial

SC to Ultra Super Critical (USC) and on to Advanced Ultra Super Critical (A-USC). Current state-of-the-art

USC plants operate at a steam temperature of 600°C, and the A-USC Toshiba is currently developing is

expected to operate at 700°C—this will further improve generation efficiency and cut CO2 emissions by a

further 10%. Toshiba participated in the A-USC development project from 2008 to 2016, working to

establish nickel-based alloy technologies for 700°C class steam turbines, and achieved excellent results.

Currently, Toshiba is promoting R&D to improve the reliability of those A-USC technologies.

Technology to capture CO2

The second approach is focused on capturing and

sequestering CO2 produced during thermal power

generation to prevent it entering the atmosphere.

There are high expectations for this approach, and

it is seen as a bridge from the fossil fuels of the

present to a bright green future.

Toshiba is focusing on using an alkaline aqueous

amine solution to capture emissions. Its

advantage is that it can be applied to existing

power plants, but the drawback is that it

consumes relatively large energy in the process of

capturing CO2. The company is gathering data on

real-world results from a demonstration project at

a thermal power plant site in Japan, and working to

lower such energy requirements. The technology

is now amongst the best in the world in this field.

Another approach Toshiba is investigating is

Carbon Capture and Utilization (CCU), which effectively

utilizes collected CO2 to useable products and fuels. Again in Japan, a CO2 separation and capture system

delivered to Saga City, a local government, and installed at a waste incinerator is capturing high purity

CO2 that is used for commercial algae cultivation at a nearby plant factory.

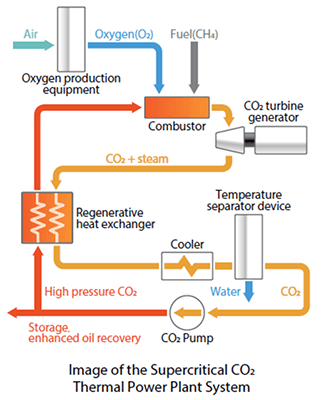

Achieving zero emission: Revolutionary generation technology to capture CO2 whilst generating electricity

Of course, the ultimate solution to CO2 emissions is to eliminate them. In order to achieve this goal,

Toshiba is developing the world's first Direct-Fired Supercritical Oxy-Combustion CO2 Power Cycle

Generation System in partnership with U.S. companies–NET Power, LLC., 8 Rivers Capital, CB&I, and

Exelon Corporation.

This advanced system achieves the same generating

efficiency as a high performance combined-cycle

power plant, and also captures CO2 at high-pressure,

securing zero emission without any increase in

electricity costs. It is also environmentally-friendly,

as the system burns natural gas with oxygen and

releases no nitrogen oxide, a source of environmental

pollution.

As one of the world's fastest growing economies,

India needs to rapidly boost its power generation

capacity while drastically lowering emission levels.

Toshiba aims to provide solutions to these

twin problems by providing industry-leading

thermal power equipment technologies and quality

FOR THE NEXT INDIA.

VISIT TOSHIBA THERMAL POWER PAGE

FOR THE NEXT INDIA